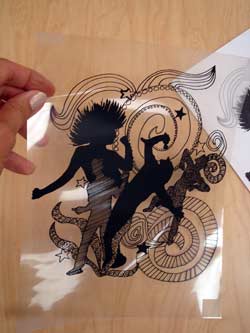

Screen printing is a printmaking technique that creates a sharp-edged image using a stencil.

Stencil is made by exposing stretched silk, covered with photo emulsion, to light.

A screen is made of silk or polyester. It is stretched over a frame of aluminum or wood. Areas of the screen are blocked off with a non-permeable material to form a stencil, which is a negative of the image to be printed; that is, the open spaces are where the ink will appear.

The screen is placed atop paper or fabric. Ink is placed on top of the screen, and a squeegee is used to fill the mesh openings with ink.

quick steps

- Draw a design. Use black&white imaging only (lines, solid black shapes, shadings: pointillism, hatching, cross-hatching)

- Transfer the design onto 2 sheets of transparency, tape them together for better light block.

- Stretch a piece of silk (or polyester mesh) over a frame.

- Apply photo-emulsion. Dry.

- Place the transparency onto the frame and expose to light (to solidify exposed areas and block the drawn areas)

- Rinse the silk to reveal the stencil. Dry.

- Place the frame over a printing surface and squeeze ink through the stencil.